Trusted by global leading organizations

The growing demand for high-performance electronics is exposing manufacturers to new risks and vulnerabilities.

Vision-AI Turns Your Supply Chain’s Black Box Transparent

From Blind Trust To Full Visibility

Authenticate every component before, during, and after assembly

Enforce BOM and AVL policies in real time

Ensure product integrity across lines, suppliers, and regions

Detect counterfeits, tampering, and sourcing errors

Significantly reduce quality failures, recalls,

and warranty claims

Use Cases

-

Cyber Physical Security

-

Supply Chain Repository

-

AVL Enforcement

-

Micro Traceability

-

Root Cause Analysis

Automated visual verification

Detecting embedded hardware threats, such as rogue chips or components designed to disrupt operations or leak data

Detecting embedded hardware threats, such as rogue chips or components designed to disrupt operations or leak data

Tampered Components

Detecting probe marks that may indicate malicious tampering

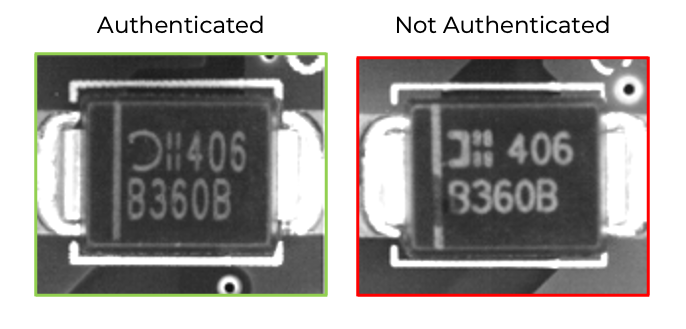

Detect Counterfeits

Using high-resolution image analysis to identify subtle differences in surface markings, material texture, and edge geometry to detect counterfeit or re-marked components

Fonts and positions are not aligned with the franchised spot text pattern

Wrong logo size and suspected text sequence

Wrong logo size and suspected text sequence

Comprehensive data on every component

used in the manufacturing process

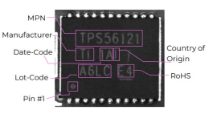

Discrete board and component Info

Discrete bottom component image

Comprehensive data on every component

used in the manufacturing process

Visualy verified date code & lot code compared to manufacturer database

Comprehensive data on every component

used in the manufacturing process

Discrete top component image

Approved Vendor List (AVL) enforcement

Visually verified component Country of Origin

Component Authenticity Enforcement

Detect counterfeit and unauthorized components in real time.

Automated Component Recognition

Compare multiple components’ visual signature against a verified database, identifying counterfeit, recycled, or non-conforming parts

Zero-Trust Component Validation

Leveraging Visual AI, the system immediately flags unrecognized components as potential counterfeits or unauthorized substitutions by matching their visual fingerprints against a database of billions of verified components.

Visually validated traceability

Visually validated traceability

Package Usage History

Detailed production logs

Detailed components package information

Reel data shows two types components, indicating an Authenticity issue

Users can drill down for additional information on a specific component including its exact location on a specific board

Deep Industry Understanding Powered by Big-Data

In Their Own Words

Cybord aligns perfectly with our commitment to enhance quality and product integrity

Hirofumi Yoshimi

In manufacturing supply chains, it’s critically important to have a competitive edge in both quality and efficiency. Cybord not only affords these advantages, but also provides enhanced security and visibility.

Renée Ure

Cybord’s state-of-the-art AI technology, provides our customers with an unparalleled ability to detect and resolve quality issues quickly and efficiently.

Markus Sauter

Industries

News

Cybord Unveils ShieldScan, a Visual-AI PCBA Inspection Solution Ensuring Cyber-Physical Security and Supply Chain Integrity

(Wilmington, Delaware, April 23rd, 2025) – Cybord, the leading provider of advanced AI-powered electronic component analytics, announces the launch of ShieldScan, an advanced visual-AI printed circuit board assembly (PCBA) inspection

Ensuring Compliance With the U.S. CHIPS Act: Identifying the Source of Electronic Components

The U.S. CHIPS Act aims to strengthen domestic semiconductor manufacturing and enhance supply chain security. As part of this initiative, manufacturers must ensure compliance with specific regulations regarding the sourcing

Cybord Unveils AI-Powered Real-Time Interception (RTI) Solution to Prevent Defective Electronic Products

The new visual AI solution prevents defective components from being assembled onto printed circuit boards in real-time, ensuring product viability while reducing manufacturing rework and scrap, will be presented at

Fuji America and Cybord Form Strategic Partnership to Deliver Visual AI-Powered Technology to SMT Production Lines Across the Americas

Reinforcing Fuji America’s commitment to industry leading solutions, this partnership will utilize Cybord’s unique technology to usher in a new era of quality in electronic manufacturing (Wilmington, Delaware and Vernon