By: Oshri Cohen, CEO, Cybord

I often ask customers how confident they are that the systems they produce truly meet their own standards. The reaction is, more often than not, an uneasy silence. I know that silence. After all, I was sitting in their seat not so long ago.

Modern electronics manufacturing has outpaced the industry’s ability to maintain full control. Systems today are incredibly complex, with tens, hundreds, even thousands of components on a single printed circuit board. Much of production is outsourced – contract manufacturers order, assemble, test, and ship finished products. OEMs are left trusting that every supplier, assembler, and technician in that chain maintains the same commitment to quality and reliability that they do.

That trust, while not misplaced, is limited by what traditional tools can realistically deliver.

We see it every day across our customers’ lines (well – our visual AI sees it). Issues ranging from unauthorized components and misrepresented traceability logs to outright defective parts. Problems that traditional systems – designed for another era – simply cannot detect.

I want to share a few real-world examples. The images you’ll see are from live installations, and rest assured, every one of these issues has since been addressed.

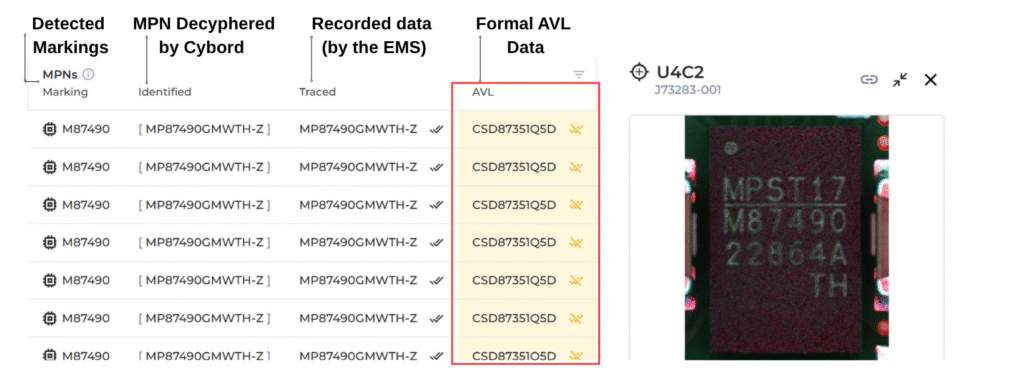

When Approved Isn’t Always Approved

Non-AVL components are one of the clearest examples. We see incidents every week where components are placed that don’t appear on the Approved Vendor List. The impact can be severe. It’s bad enough when quality components are used but haven’t been vetted by the OEM. But when unverified, low-grade, or even counterfeit parts slip through, the risks multiply. In mission-critical systems – aerospace, defense, automotive, medical – the consequences can range from costly recalls to cybersecurity risks and safety failures.

AVL Mismatch | Source: Cybord.ai

In Data We Trust (or do we?)

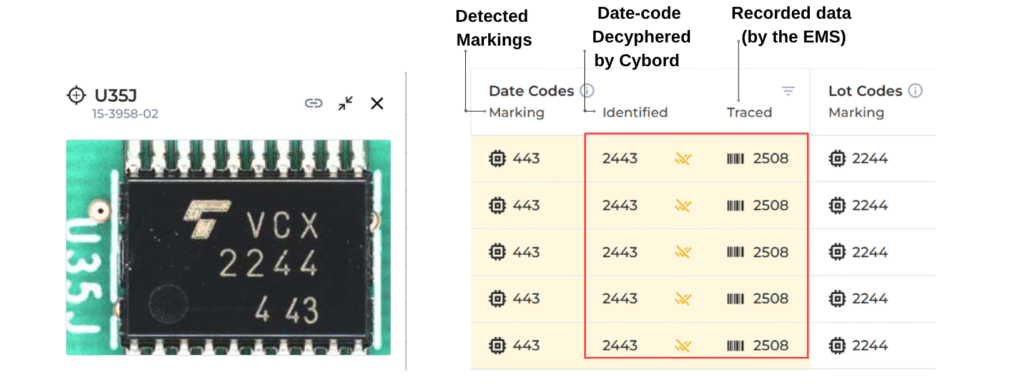

Then there’s traceability data – a seemingly administrative detail with enormous implications. We detect dozens of cases every week where the recorded Manufacturer Part Number (MPN) doesn’t match what’s actually on the board. When a recall is triggered, such errors can cause a manufacturer to pull the wrong parts or, worse, leave faulty ones in the field. A single mismatch can ripple into massive financial and operational fallout.

Incorrect manufacturing date codes appear just as often. These distort a company’s ability to track component aging and compliance, and in a recall scenario, they once again risk targeting the wrong inventory. It’s not just inefficiency – it’s a direct hit to reliability and brand integrity.

When I speak with customers, I often emphasize the difference between traceability – basic data logging, barcodes, or reel-level scans – and micro-traceability, the ability to read and decipher the markings on every single component. Without micro-traceability, you can never be certain your data reflects reality.

Date-Code Mismatch | Source: Cybord.ai

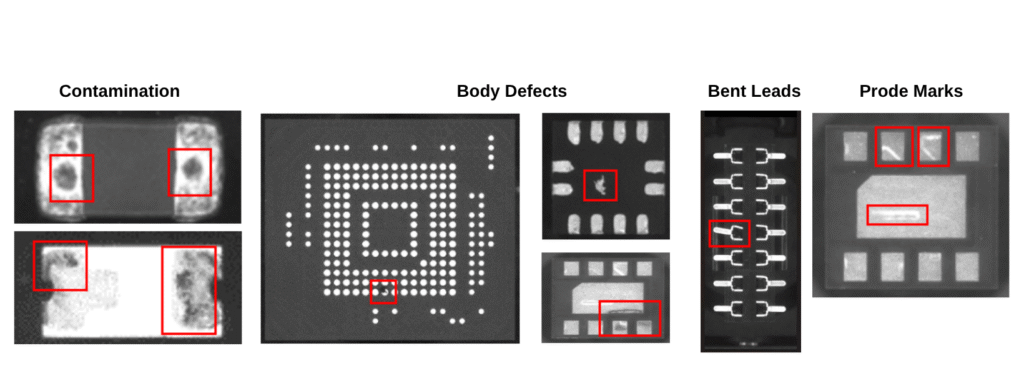

When the Problem Isn’t in the Data — It’s in the Part

Visual AI also exposes what no spreadsheet can: the physical reality of defects. We routinely identify cracked bodies, bent leads, and faulty BGAs – dozens of incidents each week, often involving thousands of components. These defects can easily pass functional testing, only to fail later in the field, where the cost of failure is exponentially higher.

Beyond structural damage, we see contamination and defective silicon — moderately common but critically impactful. These issues lead to scrap, rework, or latent failures that quietly erode profitability and reputation. Often, they originate in weak links across the supply chain, manufacturing, or storage — the very areas least visible to OEMs.

Body Defects Caught by Cybord

Why It Keeps Happening

These problems persist because existing traceability and quality systems lack both depth and automation. They rely on labels, manual data entry, and human oversight — all inherently prone to error. And while each incident may seem small, even a handful can involve thousands of components, hundreds of boards, and countless finished products.

Striving for 100%

In mission-critical industries, “good enough” isn’t good enough. Visual AI allows manufacturers to see — literally – what’s happening on their production lines. It bridges the gap between assumption and fact, between what was ordered and what was built, and between production capacity and true quality control.

When every component is verified, every defect caught, and every record matched to physical evidence – confidence replaces silence. I know that. I’ve been there.