Industry: Automotive

Challenge: Avoiding a Major Recall

Solution: Cybord Micro-Traceability

The Customer

A top-tier international OEM in the automotive industry.

The Challenge

In early 2025, the OEM received a notification from their chip supplier: several component lots shipped over multiple quarters were potentially defective. The vendor advised that any board containing chips from those lots should be recalled and replaced immediately.

The OEM turned to its EMS and requested a list of all affected boards assembled since 2024. In total, 50,000 boards were at risk.

Without a way to isolate the affected units, the OEM faced the costly and reputationally damaging prospect of a full recall. Luckily, they had installed Cybord’s Micro-Traceability solution.

Estimated Recall Costs (Without Cybord)

Here’s a rough breakdown of the expected operational costs if all 50,000 boards had to be recalled:

| Action | # of Units | Cost/Unit | Total Cost |

| Recall logistics | 50,000 | $50 | $2,500,000 |

| Lab inspection & analysis | 50,000 | $80 | $4,000,000 |

| New board production (25%) | 12,500 | $200 | $2,500,000 |

| $9,000,000 |

These figures reflect only operational costs — they do not include the reputational damage, customer retention efforts, or crisis PR often associated with large-scale recalls.

The Solution: Cybord Micro-Traceability

The EMS immediately turned to Cybord.

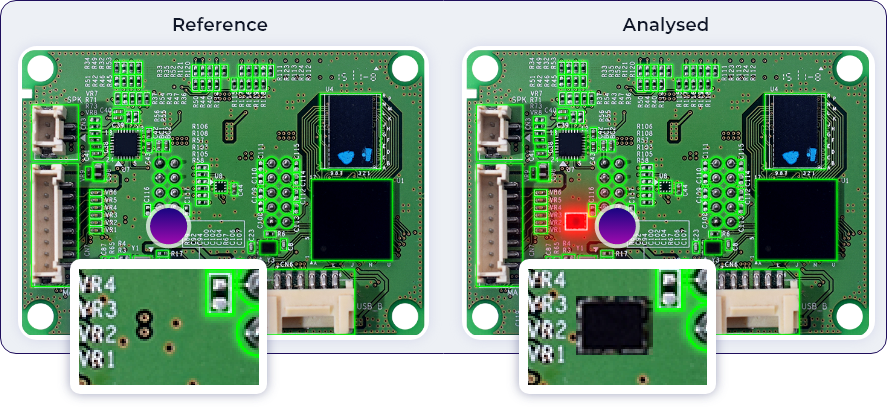

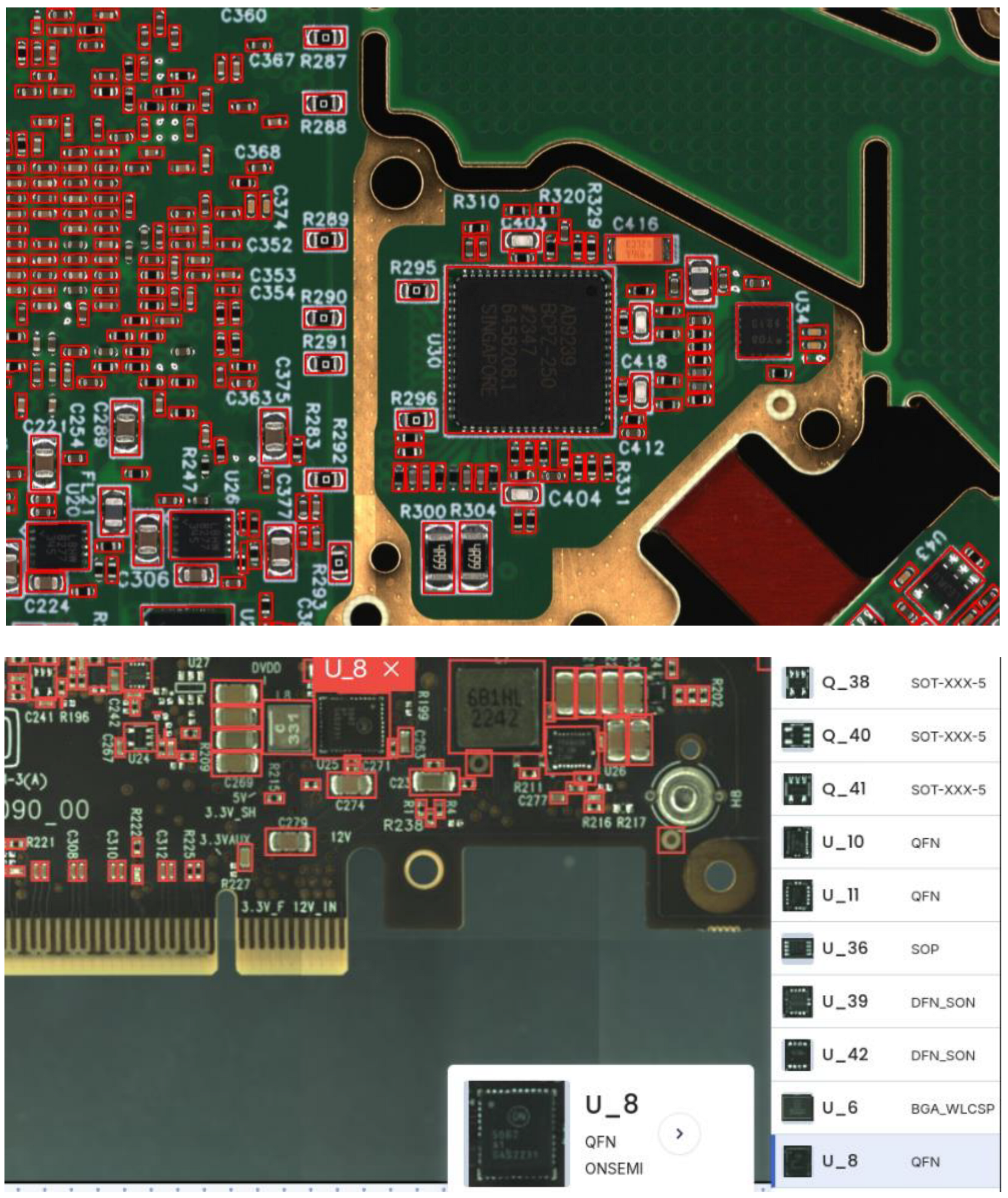

Cybord’s micro-traceability module utilizes top-side visual analysis to read and decode component markings — accurately interpreting each manufacturer’s specific coding, conventions, and variations. This information is stored to create a comprehensive repository of every component assembled on every board, including granular details such as manufacturer part number, date code, lot code, and more. Crucially, each component is linked to its corresponding board serial number, enabling unmatched micro-traceability across the production line.

Cybord’s micro-traceability module delivered the following:

- Analyzed every board image in detail

- Matched component-level data to the affected chip lot codes

- Identified only 974 affected boards – just under 2% of the total batch

Cost After Cybord Analysis

With Cybord’s analysis, the OEM could now isolate and address only the affected boards:

| Action | # of Units | Cost/Unit | Total Cost |

| Recall logistics | 974 | $50 | $48,700 |

| Lab inspection & analysis | 974 | $80 | $77,920 |

| New board production (25%) | 243.5 | $200 | $48,700 |

| $175,320 |

The Bottom Line

Operational savings: $8.82M

Risk avoided: Full-scale recall

Time to resolution: Under 1 hour

A Case for Proactive Traceability

This case underscores the value of real-time, component-level traceability integrated during production.

With Cybord’s traceability module in place from the start, the team could benefit from immediate access to verified component data — eliminating the need for emergency post-production analysis and enabling fast, clear decisions in high-stakes moments.

It’s a powerful example of how Visual AI and micro-traceability can fortify operational resilience and safeguard against unexpected supply chain risks.

Customer Quote (EMS Site Manager)

“Cybord’s micro-traceability capabilities are truly impressive. Their solution delivered exactly what we needed – full traceability and the ability to pinpoint issues with 100% accuracy. Thanks to this, our OEM customer avoided a major recall and saved significant time and cost”.