At Cybord, we recognize the critical role that existing pick-and-place and Automated Optical Inspection (AOI) machines play in production.

Cybord offers a complementary Artificial Intelligent software solution that significantly enhances your quality and productivity.

Our advanced technology integrates seamlessly with your current machinery, providing an additional layer of precision, efficiency, and reliability.

While traditional machines focus on process control, Cybord specializes in material control, ensuring the highest quality of materials used in production.

This comparison table illustrates the features supported by traditional production equipment alongside those offered by Cybord, showcasing how our AI platform elevates your production capabilities to new heights of quality and traceability.

By incorporating modern AI-based capabilities into your production lines, Cybord ensures your operations stay at the forefront of technological advancement.

cybord vs existing tools

Features content supported by Cybord AI platform:

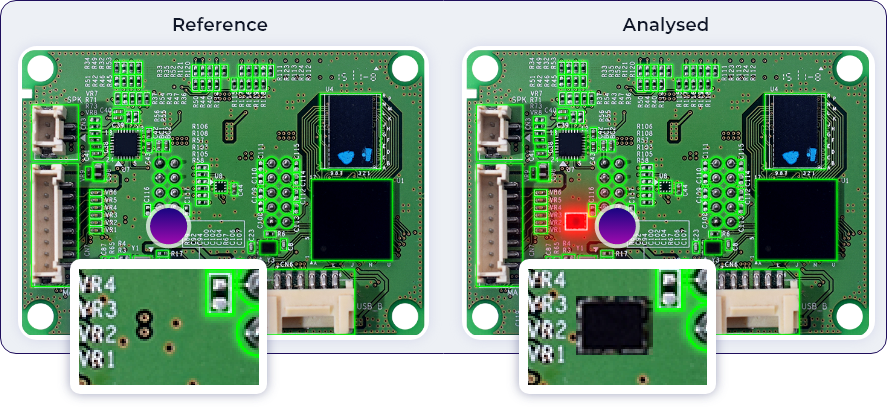

● Crack/Body defect detection – Utilizing an advanced AI deep neural network, Cybord detects even the smallest cracks on component surfaces.

● Corrosion/Contamination detection – This feature identifies contamination marks on components and their leads. Any component showing signs of contamination is flagged for further inspection. The detection threshold is adjustable, allowing customers to decide the acceptable level of contamination.

● Foreign Object Debris (FOD) Detection – Cybord’s AI algorithms inspect 100% of components, ensuring no foreign objects, which can cause shorts or weaken solder joints.

● Manufacturer Authenticity Validation – Cybord uniquely identifies the manufacturer of each component in real-time by analyzing the bottom-side image, ensuring no counterfeit or incorrect materials are used in assembly.

● Epidemic behavior Recognition – Cybord tracks material quality by its original

package (reel or tray) and alerts for epidemic failures if multiple similar defects are detected, helping prevent faulty materials from being assembled over whole

batches.

● Board-Level data consolidation – Cybord links each component analyzed to a specific board serial number, enabling the aggregation of component quality data and scoring of the assembled board.

● Component Reel Package Data Consolidation – Cybord aggregates the quality data of components by their original package, essential for identifying and addressing epidemic behaviors.

● Root cause analysis records – Every component analyzed is recorded for future root cause analysis. The Cybord portal allows querying by board SN, component package, MPN, and other criteria, facilitating thorough investigations before the physical board returns.

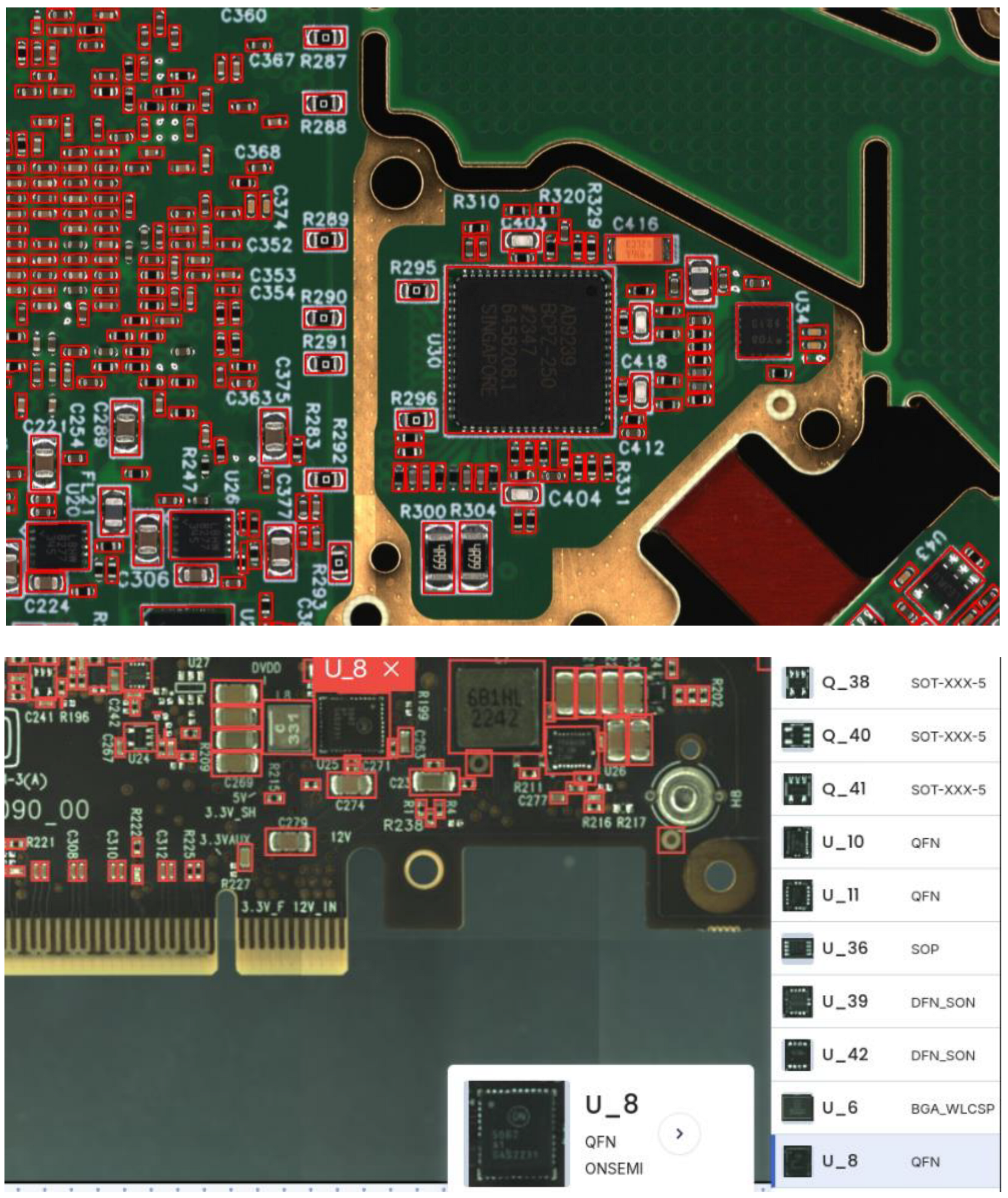

● Top Marking Pattern Recognition – Using AI for accurate pattern recognition, Cybord identifies and interprets all signs and characters on a component’s top side, continually improving with each new component encountered.

● Date-Code/Lot-Code Recognition – Cybord accurately identifies and reports the date-code and lot-code information for each component, enhancing the traceability data used.

● AVL Violation Recognition – Cybord identifies the actual manufacturer part number of each component, helping customers verify and enforce their Approved Vendor List (AVL).

● Traceability Visual Verification – Cybord offers enhanced comparison between collected traceability logs and recognized traceability information, allowing customers to validate and correct data before usage.