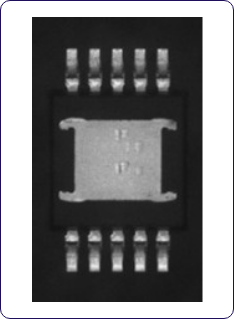

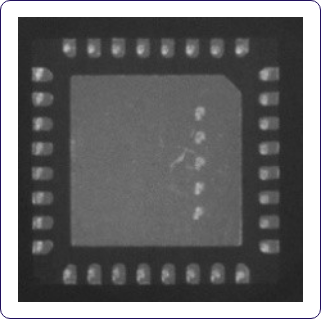

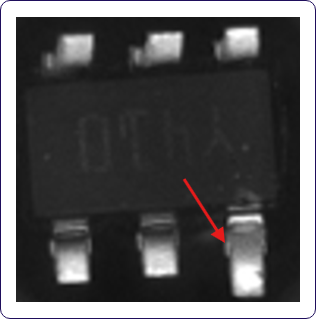

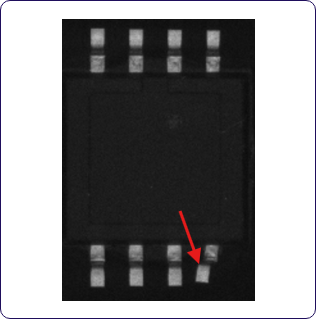

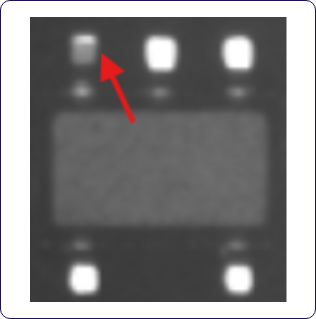

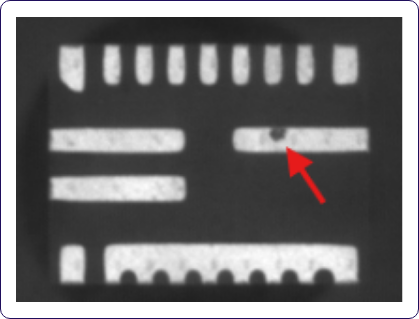

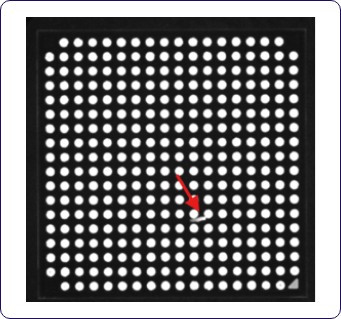

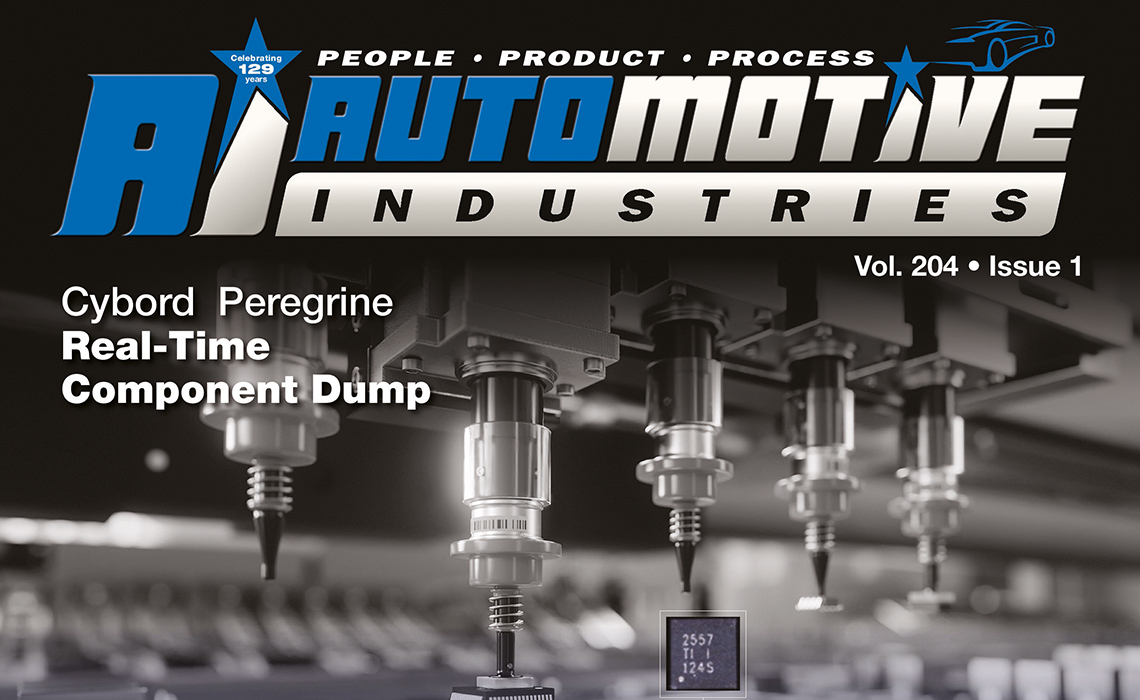

Component-Level Inspection

A Critical Moment of Verification

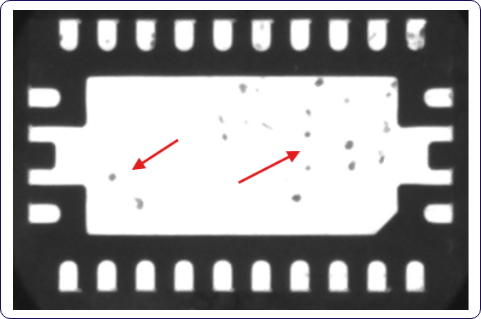

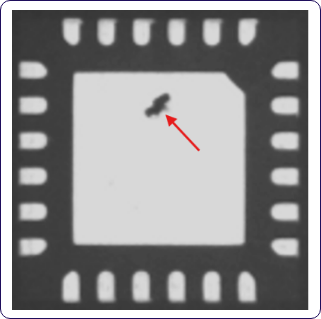

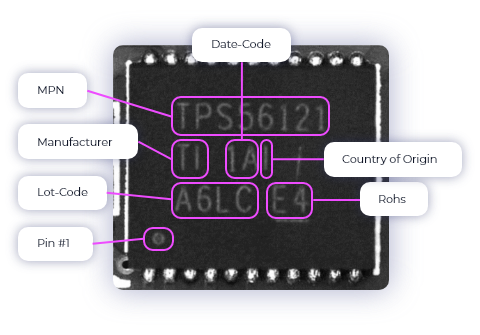

The manufacturing line offers a unique opportunity — often the first and only chance — to validate that the components assembled match the Bill of Materials (BOM) and the Approved Vendor List (AVL). Cybord’s bottom-side inspection solution captures this critical moment, helping to make sure that only authorized, high-quality components make it into product.