Collapsing the Uncertainty of Modern Electronics

In 1935, Austrian physicist Erwin Schrödinger proposed a thought experiment that would become a cornerstone of quantum mechanics lore. He imagined a cat sealed inside a box with a mechanism that had a 50/50 chance of killing it. Until an observer opens the box to look, quantum theory suggests the cat is simultaneously alive and dead – existing in a “superposition” of states.

For decades, this paradox was the domain of theoretical physics. Today, it is the operational reality of the global electronics supply chain.

When a reel of components arrives at a factory, it enters the “box” of the manufacturing process. According to the label, the paperwork, and the distributor’s promise, the components inside are authentic, new, and compliant. But given the volatility of the modern semiconductor market and the sophisticated evolution of the gray market, there is a non-zero probability that the components are actually counterfeits, harvested e-waste, or “ghost” production overruns.

Until the moment of assembly, and often until the product fails in the field, those components exist in a superposition. They are simultaneously “trusted” and “compromised.” For OEMs in aerospace, automotive, and defense, operating a Schrödinger Supply Chain is not a philosophical puzzle; it is an existential risk. To secure the future of electronics, we must find a way to open the box and collapse the uncertainty before the product ever leaves the factory floor.

The Evolution of the Threat: AI-Generated Counterfeits

The electronics supply chain is facing a new kind of threat: not crude counterfeit chips, but sophisticated reclaimed components enhanced by AI-driven deception. As high-performance systems are rapidly replaced, large volumes of used chips enter the “harvest-and-resell” pipeline, where they are cleaned, resurfaced, and re-marked to appear new. These parts are often functional but have been thermally stressed or degraded, creating a “Schrödinger state”; They may pass initial tests but carry hidden damage that can lead to failure in real-world conditions.

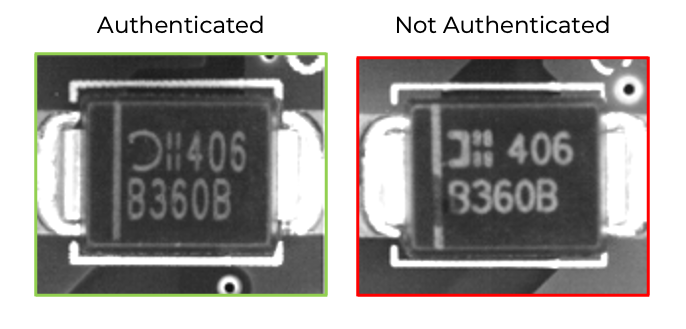

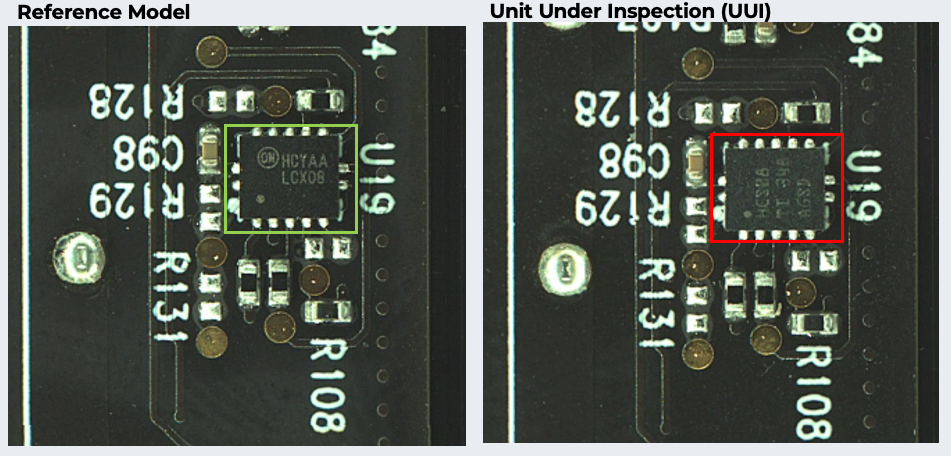

Authenticated vs. Not Authenticated Component

Compounding the problem, counterfeiters now use AI to generate highly convincing labels, packaging, documentation, and even fake compliance reports that can pass standard inspections. Traditional methods—such as sampling, paper verification, or basic electrical tests – are increasingly ineffective against these optimized fakes. As a result, manufacturers relying on conventional validation methods are unknowingly accepting statistical risk instead of verifying component integrity with certainty, exposing products, customers, and brand reputation to hidden reliability and security risks.

This latest pressure on an already stressed supply chain joins a host of other issues we have almost grown accustomed to over the past 18 months. These include geopolitical volatility, the “AI frenzy” and resulting component shortages, hardware cybersecurity incidents, and escalating regulatory burden.

The Observer Effect: Visual AI as the Ultimate Truth

In quantum mechanics, the act of observation collapses the wave function, forcing the system to choose a single state. In electronics manufacturing, Visual AI provides this observation capability at scale.

To dispel the uncertainty of the Schrödinger Supply Chain, OEMs need a technology that can “look” at every single component, not just a sample, and not just the label on the reel. This is the core of Zero Trust Manufacturing. By integrating AI-driven software directly into existing pick-and-place machines, manufacturers can utilize the high-resolution cameras already present on the line to act as the “observer.”

As each component is picked up, the AI analyzes its bottom side in milliseconds. It scrutinizes the leads for micro-corrosion or oxidation that suggests improper storage or age. It checks for probe marks that indicate the part has been previously used or reprogrammed – a telltale sign of the “harvest-and-resell” pipeline. It analyzes surface texture and mold marks to verify they match the specific “fingerprint” of the authentic manufacturer, rather than a resurfaced clone.

AVL Mismatch – Component Relacement

Simultaneously, top-side inspection reads and verifies the markings on the component body. It validates date codes, lot codes, and country of origin against the Approved Vendor List (AVL). In this split second, the superposition collapses. The component is no longer “possibly good” or “possibly bad.” It is definitively verified as authentic – or it is flagged as a risk and rejected.

From Probability to Micro-Traceability

The impact of collapsing this uncertainty extends beyond the assembly process. It creates a permanent record of truth known as micro-traceability.

Consider a scenario where a specific lot of chips is discovered to be defective months after production. In a traditional, “uncertain” supply chain, the OEM knows they purchased the reel, but they do not know exactly which boards contain the specific parts from that reel. They are forced to recall thousands of units based on probability.

With micro-traceability, the OEM has a digital “birth certificate” for every board. They can search their database and identify the exact boards that contain the specific date codes or visual signatures in question. They turn a probability problem into a data problem. The recall becomes surgical, precise, and dramatically less expensive.

Conclusion: Certainty Is a Choice

The metaphor of Schrödinger’s cat persists because it perfectly captures the anxiety of the unknown. For too long, electronics manufacturers have accepted this uncertainty as the cost of doing business. They have accepted that global supply chains are opaque “boxes” into which we cannot see.

But the box is becoming more dangerous. The combination of high-velocity technology turnover and AI-enabled counterfeiting means the probability of finding a “dead cat” inside is rising.

With the integration of Visual AI and micro-traceability, we now have the tools to observe every single “atom” of the supply chain as it is assembled. We can detect reclaimed parts, reject counterfeits, and verify aging stock in real time. We no longer have to hope components are good. We can know. In an industry where reliability is paramount, choosing to remain in a state of uncertainty is no longer viable.

It is time to open the box.