The Nexperia chip crisis has once again exposed the fragility of global electronics supply chains. As automakers scramble to contain the fallout, Tesla’s mandate to remove Chinese-made components from U.S. production showcases the opposite response – proactive resilience. Together, they mark a turning point: from reacting to disruption to enforcing zero-trust manufacturing as the new standard – and why supply-chain transparency is now mission-critical.

By Oshri Cohen, CEO, Cybord

The latest disruption from Nexperia’s semiconductor plants in China has reignited fears of another global chip shortage — one that could once again cripple automotive and electronics production worldwide. Following weeks of halted exports tied to a geopolitical standoff between Beijing and the Dutch government, automakers such as Nissan, Honda, and Bosch have already been forced to curtail output.

The episode underscores how fragile the world’s component ecosystem remains. Even the smallest, cheapest chips – long considered safe from disruption – can now become instruments of geopolitical leverage. Analysts warn that supply disruptions like Nexperia’s could cascade through the industry in the coming months, triggering renewed scrambles for parts.

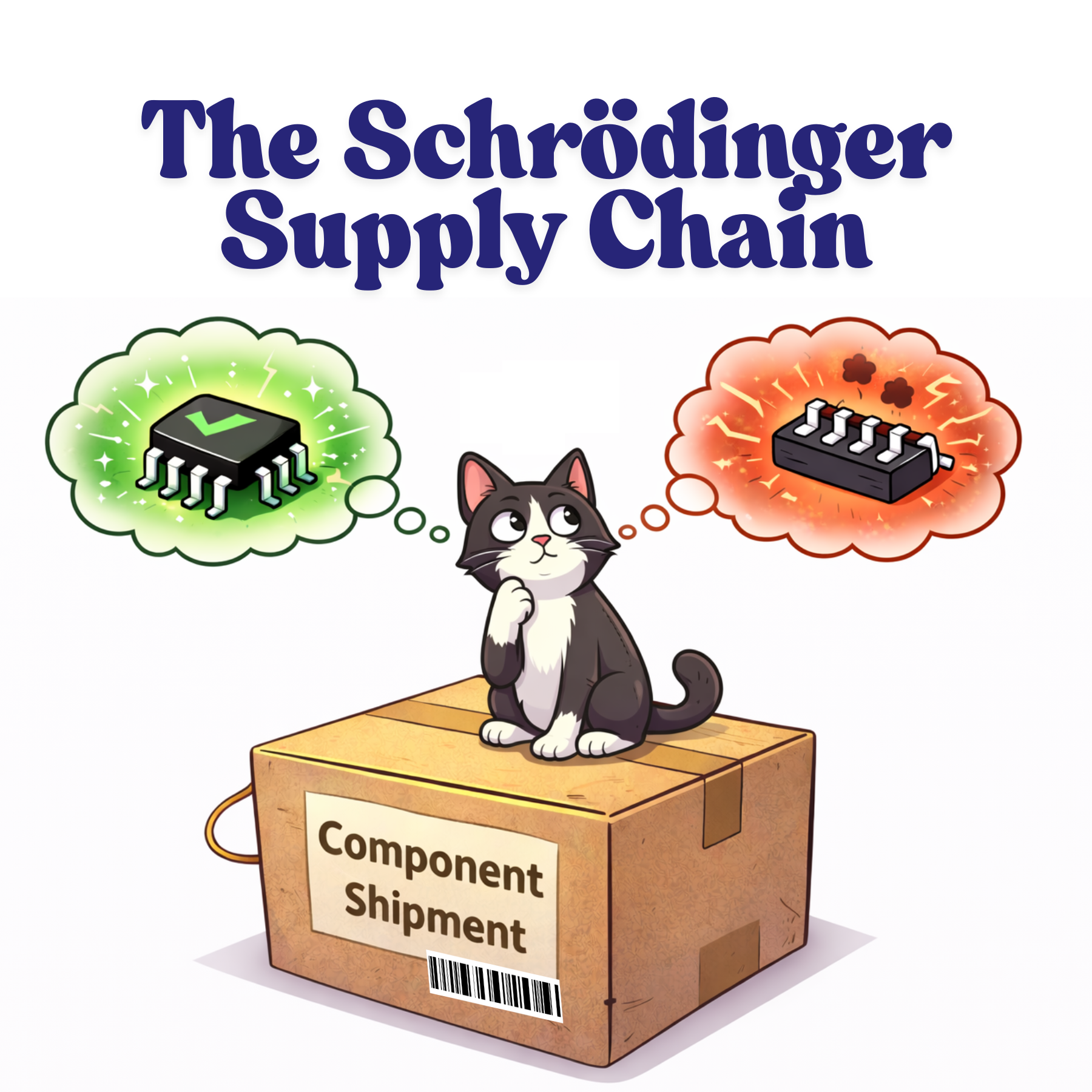

And history shows what happens when supply chains panic: quality gives way to availability.

The Hidden Cost of Shortages

When manufacturers rush to secure scarce components, the global procurement floodgates open. Brokers, gray-market suppliers, and shadow inventories emerge overnight. In past crises, such conditions have led to aged, reused, relabeled, and counterfeit components entering production lines – sometimes undetected until catastrophic failures occur.

In industries where lives and national security are on the line – aerospace, defense, automotive, data-centers and energy – that risk is unacceptable. The Nexperia disruption serves as a reminder that documentation and trust are not enough. What’s needed is proof – verified, physical, and granular.

The End of Blind Trust in Manufacturing

Traditional safeguards such as sample inspections or supplier certifications operate on outdated assumptions. When every product contains hundreds or thousands of components from multiple tiers of suppliers, paper-based assurance simply can’t scale.

The solution lies in visual inspection of each and every component. Emerging Vision-AI technology now enables this type of visual inspection at scale. What’s more, it introduces for the first time micro-traceability – the ability to inspect, verify, and digitally record each individual component – no matter how small – as it moves through production.

Seeing What Paper Can’t

Vision-AI is a software layer that uses the high-resolution cameras already embedded in production equipment like Pick-and-Place and AOI systems. It captures images of every component before and after placement on the PCB, utilizing advanced algorithms to analyze each part:

- Verify authenticity and source against approved supplier data.

- Read and decode markings to confirm manufacturer and lot details.

- Extract metadata including part number, date code, and country of origin.

- Create a digital visual record — a forensic trail for every component and board.

This process enforces compliance with an OEM’s Bill of Materials (BOM) and Approved Vendor List (AVL), instantly flagging any deviation — whether it’s a counterfeit, reused, or non-approved component — before the product leaves the line.

From Reaction to Prevention

While Nexperia’s crisis exposes systemic fragility, some manufacturers are already moving to prevent such risks. Tesla’s recent mandate requiring suppliers to remove all China-made components from U.S. vehicle production within two years exemplifies this shift toward proactive supply-chain governance.

Tesla’s strategy underscores a new mindset spreading across high-reliability sectors: assume nothing is safe until it’s verified. This Zero-Trust Manufacturing approach replaces faith with evidence – every component must prove its authenticity and origin.

The Road Ahead

The Nexperia crisis is a warning shot. As geopolitical friction rises and inventories tighten, another round of global component shortages appears imminent. When that happens, the temptation to buy whatever is available – regardless of provenance – will be overwhelming.

Manufacturers that adopt micro-traceability through Vision-AI will be the ones able to keep producing confidently, knowing that every resistor, capacitor, and chip on their boards is genuine, approved, and safe.

In an era where the supply chain itself has become a battlefield, seeing is not just believing – it’s surviving.